Within FCAW , seamless cored wires offer optimal protection against moisture reabsorption.

During use, moisture cannot penetrate into the filling since there is no closed seam running over the wire length. This extremely low level of diffusible hydrogen prevents the weld from hydrogen induced cracking or cold cracking.

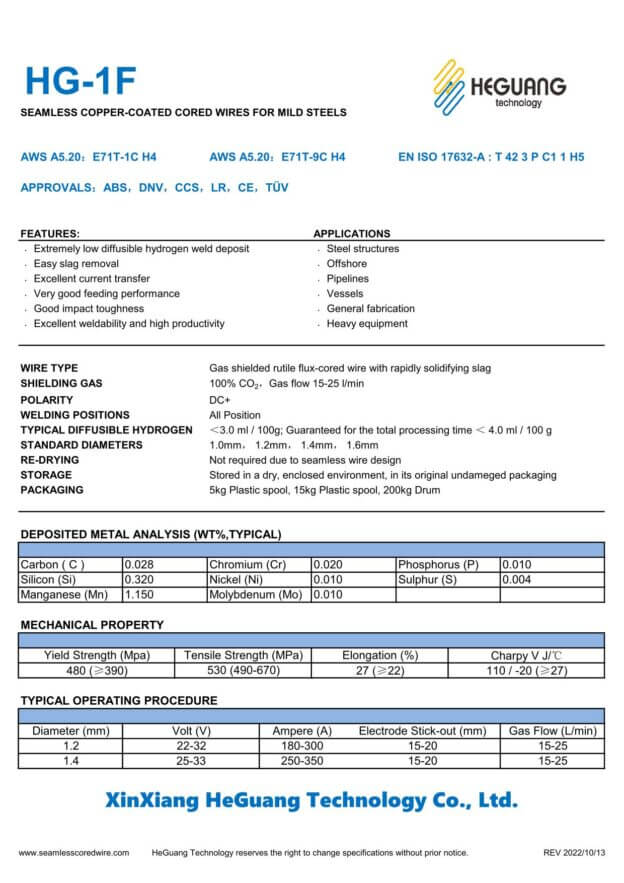

HG-1F / E71T-1C is a seamless rutile flux cored wire applicable for all-positional welding with

100% CO2 shielding gas.

Thanks to its unique seamless structure, HG-1F / E71T-1C generates low spatter and has excellent impact properties in low temperature.

These properties make HG-1F / E71T-1C the perfect seamless cored wire for industries such as shipbuilding, steel construction, bridges, offshore, pipes, and pressure vessels.

Features & Benefit

- Optimal protection against hydrogen induced cracking, due to ultra-low diffusible hydrogen content (under 3ml/100g weld metal)

- Stable welding arc with low spatter and perfect weld bead

- Good weldability in all positions and less post-weld cleaning

- Unique seamless structure allow excellent feedability and electrical conductivity

- Use 100% CO2 shielding gas

- Excellent impact properties in low temperature, down to -30°C (-20°F) in pure CO2 gas